Sixth in a series of related articles reviewing the roles that have been identified when working with cranes, explaining Riggers’ responsibilities, defining their training requirements, and outlining their documentation requirements.

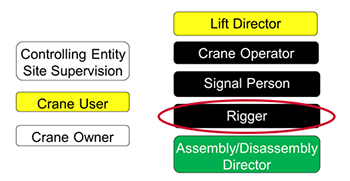

September 5, 2022—As stated in our previous articles, the roles on the left side of the graphic (right) are roles that do not have any requirements for qualification (e.g., competent, certified, or qualified). The roles on the right side, however, do have prescribed qualifications and responsibilities.

September 5, 2022—As stated in our previous articles, the roles on the left side of the graphic (right) are roles that do not have any requirements for qualification (e.g., competent, certified, or qualified). The roles on the right side, however, do have prescribed qualifications and responsibilities.

Riggers are a key area of responsibility when working with cranes. This role typically hooks and unhooks the loads from a crane. OSHA focused on this area and now ASME has weighed in as well.

Under OSHA, the rigger must be a qualified person and is required when hooking/unhooking or guiding a load, doing the initial connection of a load to a component or structure, rigging during assembly/disassembly of a crane/derrick, or anytime workers are within the fall zone.

The fall zone means the area (including, but not limited to, the area directly beneath the load) in which it is reasonably foreseeable that partially or completely suspended materials could fall in the event of an accident. Said another way, where will the load wind up if it fell? If the load is round and can roll, there might be a much bigger fall zone than the “drop” area.

In 2018, ASME added the role of rigger into the B30.5 standard. It states in part, “The rigger selects, configures, and assembles the rigging equipment for the attachment, support, control, and detachment…”

In 2018, ASME added the role of rigger into the B30.5 standard. It states in part, “The rigger selects, configures, and assembles the rigging equipment for the attachment, support, control, and detachment…”

ASME went further by outlining the rigger’s responsibilities as:

- Ensuring the weight of the load and its approximate center of gravity have been obtained

- Selecting the proper rigging equipment, inspecting it, and complying with applicable ASME volumes

- Ensuring the rated load of the rigging equipment as configured is sufficient for the load based on the number of legs, hitch, and effects of angles

- Properly attaching the rigging equipment

- Ensuring that rigging equipment is adequately protected from abrasion, burring, or other damage during load handling activities

- Rigging the load in a manner to ensure balance and stability

- Knowing and understanding the applicable signals for equipment in use

Further, the Lift Director’s role was modified to overseeing the Rigger.

In 2021, ASME B30.5 added rigger qualifications to include a written and practical examination covering:

- Selection and use of rigging

- Appropriate application

- Weight, center of gravity, loading

- Inspection criteria

ASME also specified that riggers who don’t meet the requirements are trainees and therefore require direct supervision by a qualified rigger.

Get more information about CCO Rigger certifications (Level I and Level II).

By CCO CEO Thom Sicklesteel, a voting member of ASME B30.5 and an alternate on B30.

View the other articles in this series: